Custom & OEM Metal Manufacturing Solutions

Automated, customizable, and ready to scale. Precision metal engineering for data centers, medical, defense, energy/nuclear, and transportation.

Request a ConsultationWhat We Deliver

The Future of Manufacturing & Fabrication

This is what the future of manufacturing looks like: precise automation and advanced technology paired with human craftsmanship and expertise.

Future Form delivers enterprise-ready manufacturing built for quality, speed, and repeatability. As a leading manufacturer with 50+ years of experience and an automation-first facility, we ensure every product is designed to your business’s unique needs and is delivered on time, every time.

Core Services

Precision Component

Manufacturing Services

Consistency You Can Count on, Automated

Sheet and tube cutting with precision. Our TRUMPF systems and skilled operators ensure every edge is clean and consistent, whether it’s a one-off prototype or a thousand identical parts. Decades of experience guide every cut, blending automation with craftsmanship to keep quality exact and timelines tight.

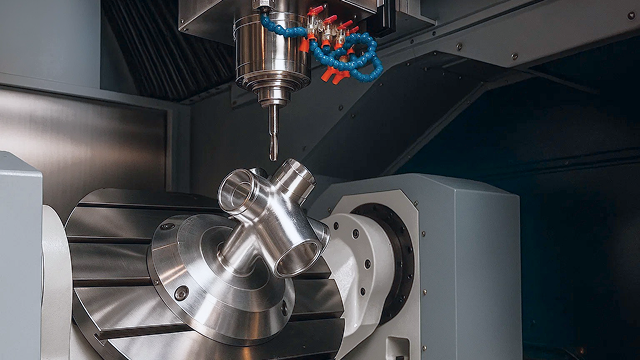

5-axis capability for complex geometries. Every component is machined by seasoned professionals who know how to translate precision engineering into real-world results. Multi-axis setups reduce operations and improve accuracy, while our experienced team ensures complex parts are produced efficiently and finished flawlessly.

HP MJF 5200 for prototyping and production-grade polymer components. Our additive manufacturing specialists combine advanced equipment with hands-on knowledge to turn digital designs into functional, production-ready parts. This process complements traditional fabrication, giving clients faster iterations, lighter assemblies, and the flexibility to move seamlessly from prototype to scale.

Manual and robotic welding for both aesthetics and repeatability. From precision TIG seams to structural MIG joints, our welders bring artistry and control to every assembly. Automated cells handle the heavy lifting, but it’s human skill that ensures each finished part meets the exacting standards our name is built on.

TRUMPF robotic bend cells automatically bend metal from programmed instructions, providing fast, repeatable production at volume. TruBend manual press brakes let operators manipulate the metal by hand, offering craftsmanship and a high degree of customization. Together, they combine automation and human skill to deliver precision parts at scale.

Assembly, kitting, packaging, and warehousing, from line to loadout. Future Form integrates subassemblies, packaging, and shipping into one smooth process. Veteran technicians manage each step, ensuring every kit arrives deployment-ready, properly labeled, and fully traceable — reducing vendor counts and keeping client schedules on track.

Our automated powder coating line applies durable finishes to hundreds of components each day, from surface prep to fully baked and cured parts. Skilled technicians monitor every stage to ensure even coverage, consistent color, and long-lasting protection. The result is a clean, uniform finish that meets both aesthetic and performance standards.

Core Industries

Metal Manufacturing & Engineering for Mission-Critical Industries

From data centers to defense, medical, energy, and transportation — we’re a metal manufacturing partner producing quality products at scale.

From initial engineering through packaging and logistics, we manage every step of the manufacturing process under one roof. Our veteran craftspeople combine decades of experience with advanced automation, ensuring agility, precision, and consistency at every stage. Continuous quality checks throughout production have earned us a 99.9% product acceptance rate — proof that every part leaving our facility meets the highest standards of accuracy and reliability.